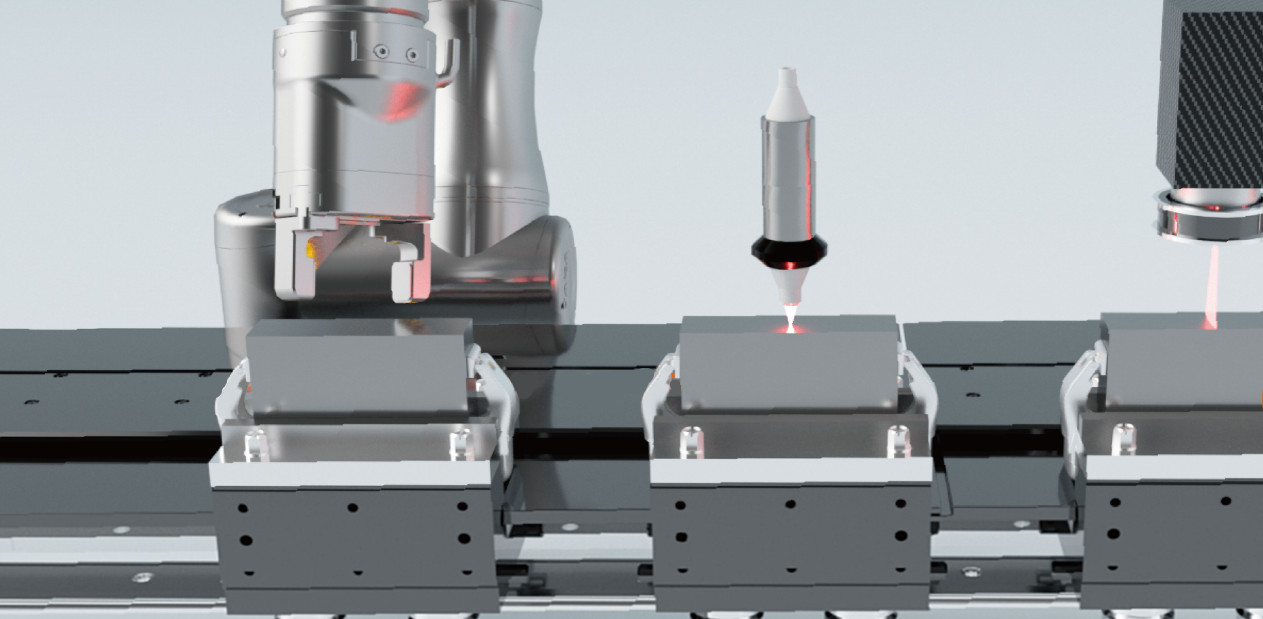

When electric grippers are applied in circular production lines, they can achieve a series of complex operations and functions to improve production efficiency and automation. Below are detailed use cases.

1. Material supply and receipt

In circular production lines, electric grippers can be used in the material supply and receiving process. Grippers can grab raw materials or parts from the supply area and pass them to the next workstation. The design of the gripper jaws allows them to adapt to different types and sizes of materials and remain stable during transportation.

2. Component assembly

During the assembly process, electric grippers play a key role. They can be used to grab and position components and then install them into specific locations within a product. The gripper's mechanical structure and control system enable highly accurate component positioning and connection, ensuring product quality and consistency.

3. Product inspection and testing

In circular production lines, electric grippers can be used during the inspection and testing phase of the product. Grippers can be used to grab and place products onto inspection equipment or test equipment. Once the test is complete, the gripper can move the product to the next workstation or divert it to another path, taking appropriate action based on the test results.

4. Packaging and Shipping

Electric grippers also play an important role in packaging and shipping. Grippers can be used to pick up assembled products and place them into packaging containers such as boxes, trays or bags. Precise control of the gripper jaws ensures products are placed correctly and packaged safely. The grippers can then move the packaged products to the shipping area or logistics center.

5. Adjust and reposition

Adjustments and repositioning are common operations on circular production lines. Electric grippers can be used to grab and move parts or products for repositioning, adjustment or correction. This flexibility allows production lines to switch between different products or processes without shutting down or resetting the entire line.

6. Troubleshooting and maintenance

Electric grippers can also be used for troubleshooting and maintenance operations. When a workstation has a problem or needs maintenance, the grippers can be used to grab and move equipment or tools for repair or replacement operations. The precision and reliability of the grippers ensure efficient troubleshooting and maintenance processes.

8. Multi-process collaboration

Circular production lines often involve collaboration between multiple processes and workstations. Electric grippers can be used to transfer materials and products between these processes. They move materials from one workstation to another, ensuring smooth connections between processes and process consistency.

9. Flexible production and product customization

As the market demand for personalized products increases, flexible production and product customization have become trends in modern manufacturing. Electric grippers enable quick adjustments and product changeovers in circular production lines. With proper programming and settings, the grippers can be adjusted to different product specifications and requirements to accommodate the flexibility and customization of the production line.

10. Human-machine collaboration

In some cases, electric grippers can also collaborate with humans. For example, during assembly, grippers can assist operators in positioning and joining parts, providing additional stability and precision. This kind of human-machine collaboration can improve work efficiency and personnel's work experience, making the production line more efficient and safer.

In summary, electric grippers have a wide range of applications in ring production lines. They can grab, move and place items to automate operations and improve production efficiency and quality. These cases are just some of them. In fact, the applications of electric grippers in ring production lines are very diverse and can be customized and adjusted according to specific industry and application needs.

Post time: Nov-06-2023