Grippers can be divided into several types, including electric and pneumatic. So, what is the difference between electric grippers and pneumatic grippers?

1: What is an industrial gripper?

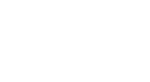

Industrial grippers are also known as mechanical gripper mechanisms. The robot gripper mechanism is designed according to the actual work requirements and has various forms.

Mechanical grippers are generally two-finger grippers, which are characterized by motion, gripping and mechanism properties. Next, let’s talk about a few important aspects. One is the pneumatic end clamping mechanism, which is characterized by very fast action speed, fluidity comes from the hydraulic system, relatively small pressure loss, and is suitable for long-distance control. The second is the suction end clamping mechanism, which uses the suction force of the suction cup to move the object. It is mainly suitable for objects with a moderate increase in appearance ratio and thickness, such as glass, just paper, etc. One is a hydraulic end clamp mechanism that clamps objects by hydraulic clamping and spring release. But, at the end of the day, the claws of industrial robots can help us do our jobs better.

2. The difference between electric gripper and pneumatic gripper

Compared with pneumatic grippers, the application of electric grippers in the field of industrial automation has the following characteristics:

1), the electric motor type has a self-locking mechanism, which can prevent the workpiece equipment from being damaged by power failure. Compared with pneumatic grippers, it is safer;

2), the electric gripper has a programmable control function to achieve multi-point positioning. Pneumatic grippers only have two stops, while electric grippers can have more than 256 stops. The acceleration and deceleration of the electric finger can be controlled to minimize the impact on the workpiece.

3), the electric gripper is a flexible gripper that can achieve precise force control, while the pneumatic gripper is an oscillating process. In principle, there is oscillation, which is difficult to eliminate. The clamping force of the electric gripper can be adjusted to realize closed-loop force control. The clamping force accuracy can reach 0.01N, and the measurement accuracy can reach 0.005mm. The strength and speed of pneumatic grippers are basically uncontrollable, so they cannot be used for fine work with high flexibility.

4), the volume of the electric gripper is much smaller than that of the pneumatic gripper. It is also very convenient to install. Maintenance is simple.

3. Advantages of electric gripper

1. Control the position of the jaws

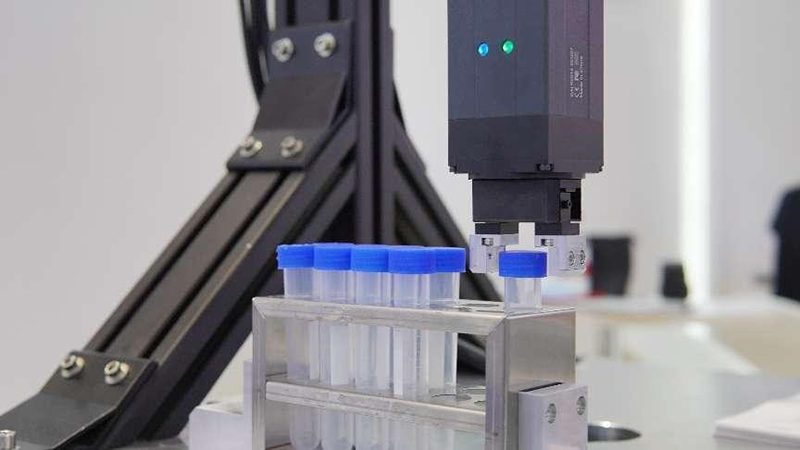

The position of the jaws can be determined by using an encoded motor and an appropriate control scheme. In contrast, with traditional jaws, it is usually necessary to hold the full stroke. When using electric grippers, use only the necessary clearance close to the part and then minimize travel. Part switches facilitate selection of a wider range of part sizes without compromising production cycle times.

2. Control grip and speed

Since the motor current is directly proportional to the applied torque, it is possible to control the applied grip force. The same goes for closing speed. For example, this might help with fragile parts.

Post time: Dec-19-2022